BMS (Battery Management System)*

Role and General Principle

The BMS (Battery Management System) is an electronic device responsible for protecting, monitoring, and managing the battery module.

It is an essential element of any electrical system using batteries, ensuring safety, performance, and longevity.

The BMS provides real-time monitoring:

of each cell's voltages,

of the charging and discharging current,

of the temperatures of the battery module.

Its aim is to make the most of the battery's energy potential while protecting it from harmful conditions in the short or long term (overcharge, deep discharge, overcurrent, overheating…).

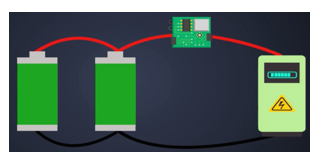

Installation and Operation

The BMS generally takes the form of an electronic board installed as close as possible to the battery.

It is powered directly by the battery it protects, allowing it to operate autonomously, even when the overall system (vehicle, machine, tool, etc.) is off.

Main Functions of the BMS

1. Overvoltage Protection

The BMS prevents overcharging of the cells, which could cause their deterioration or even destruction.

Each manufacturer specifies a maximum voltage not to be exceeded:

Example: for a LiFePO₄ cell, the maximum voltage is 3.65 V.

2. Undervoltage Protection

The BMS automatically isolates the battery to prevent a too deep discharge, which would significantly reduce its lifespan.

Example: for a LiFePO₄ cell, the minimum voltage is 2.5 V.

3. Overcurrent Protection

The BMS also protects the battery against:

short circuits,

excessive discharge currents.

These situations can lead to dangerous overheating and destroy the cells.

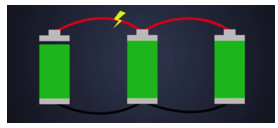

4. Cell Balancing

The BMS provides a balancing function between the different cells of a module.

It brings all cells to an identical voltage to ensure uniform wear and extend the overall lifespan of the pack.

Result: improved efficiency and better stability over time.

5. Temperature Measurement and Management

Modern BMSs integrate one or more temperature sensors.

They allow:

to cut off charging if the battery becomes too hot,

or to block recharging if the temperature is too low.

Thus, the cells and the electronic board are protected against abnormal temperatures.

6. Configuration and Customisation

Advanced BMSs allow fine-tuning, including:

the number of cells in series,

upper and lower thresholds of voltage and current,

the balancing speed,

or even customised temperature limits.

These settings allow for precise control of the battery, optimising both safety and performance.

In Summary

| Main Function | Role of the BMS |

| Overvoltage Protection | Prevents cell overcharging |

| Undervoltage Protection | Prevents deep discharge |

| Overcurrent Protection | Prevents short circuits and overheating |

| Cell Balancing | Equalises voltages to extend lifespan |

| Temperature Management | Cuts charge/discharge if temperature is abnormal |

| Custom Configuration | Adjusts thresholds and parameters according to the application |

The BMS is therefore an indispensable component in any modern battery system. It acts as an electronic brain, ensuring the safety, performance, and durability of the battery pack, whether it is an electric vehicle, an industrial tool, or an energy storage system.

*: The technical information presented in this article is provided for guidance only. It does not replace the official manuals of the manufacturers. Before any installation, handling, or use, please consult the product documentation and follow the safety instructions. The site Torque.works cannot be held responsible for inappropriate use or incorrect interpretation of the information provided.